This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Innovations with SafetyPlastic

Demand Drives Oakwood Plant Expansion

March 11, 2013General Motors Supplier Quality Excellence Award – 2013

September 4, 2013Corporate Average Fuel Requirements (CAFE) standards continue to be a strong focus of the automotive industry with the steady increases in fuel prices and evolving government regulations. Understanding the need for our customers to meet stricter CAFE standards, Oakwood Energy Management has continued to innovate and enhance our proprietary SafetyPlastic energy absorber product. Working with Grand Rapids-based Extol, and Ford Motor Company, Oakwood was able to develop and introduce a new concept of attaching the SafetyPlastic energy absorbers to headliner substrates.

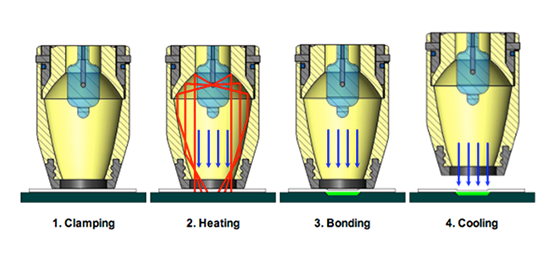

This new process, called InfraWeld, allows our customers to weld the polypropylene SafetyPlastic head impact countermeasures directly to the headliner surface thereby eliminating the need for hot melt glue during the attachment process. This innovative process eliminates approximately one pound of glue normally used to secure energy absorbing parts to the surface. In addition, by eliminating the glue from the assembly plant, safety conditions are vastly improved and the potential for hot glue accidents eliminated.

Ford Motor Company has since integrated the process onto several vehicles such the F-Series Truck, Explorer, and Escape models. This type of innovation is one way Oakwood is the industry leader in energy absorbing overhead systems and is continuously looking for ways to innovate our products.